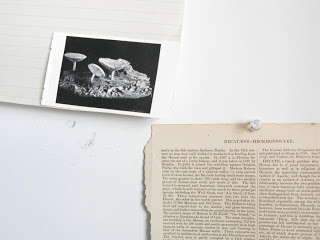

:: hecate and mushrooms ::

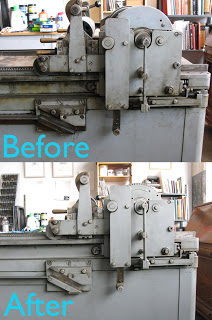

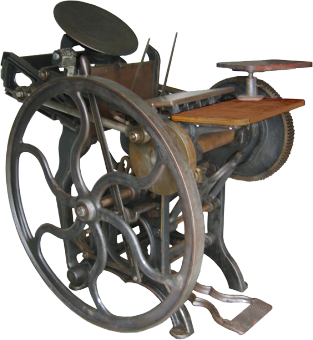

I've started the process of cleaning up my new-to-me Vandercook No. 4. I'm still a bit in disbelief. When I started cleaning it I kept having to remind myself - you're not at work (I work in a university print shop) you're cleaning your very own press.

:: clean rollers ::

The cleaning process is a real rabbit hole. There's hard dried ink lurking everywhere and it does not want to come off. It's very satisfying though when you finish one area, like the rollers, and move on to the next one.

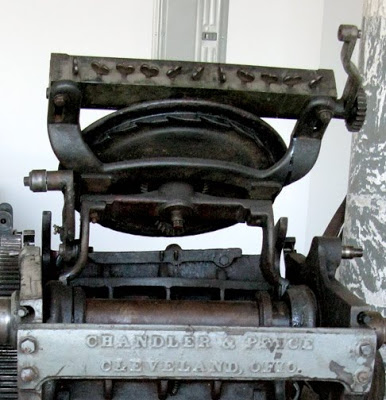

:: ink and paint composition ::

I'm also learning more about the press as I clean it. When I got home and removed the tympan paper. I found prints with the press name The Stone House Press, a fine press in Roslyn, New York run by Morris A. Gelfand.

I found this photograph of Morris.

:: Morris A. Gelfand ::

Thank you, Morris. I will treat your press well.

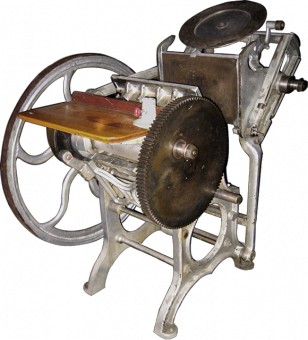

:: results ::